HJ Lubtronic 2.0 SIP

Click on a hotspot if you want to explore HJ Lubtronic 2.0 pump or the HJ SIP valves in the cylinder liner.

Watch the entire video via the Play video button below and explore the Delta-timing algorithm (Cylindercare Pro)

HJL360 » HJ Lubtronic 2.0 SIP Overview » HJ Lubtronic 2.0 SIP

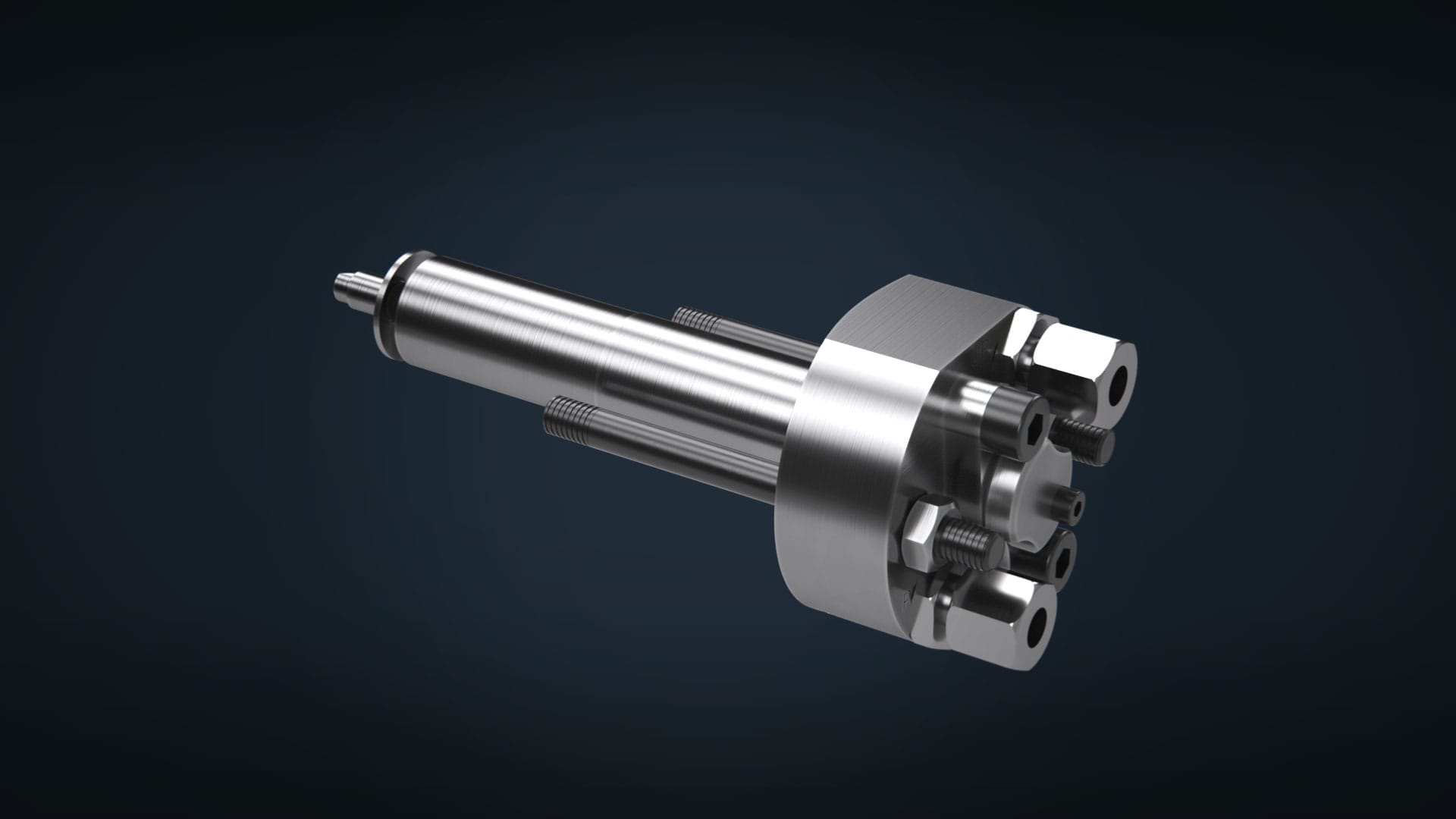

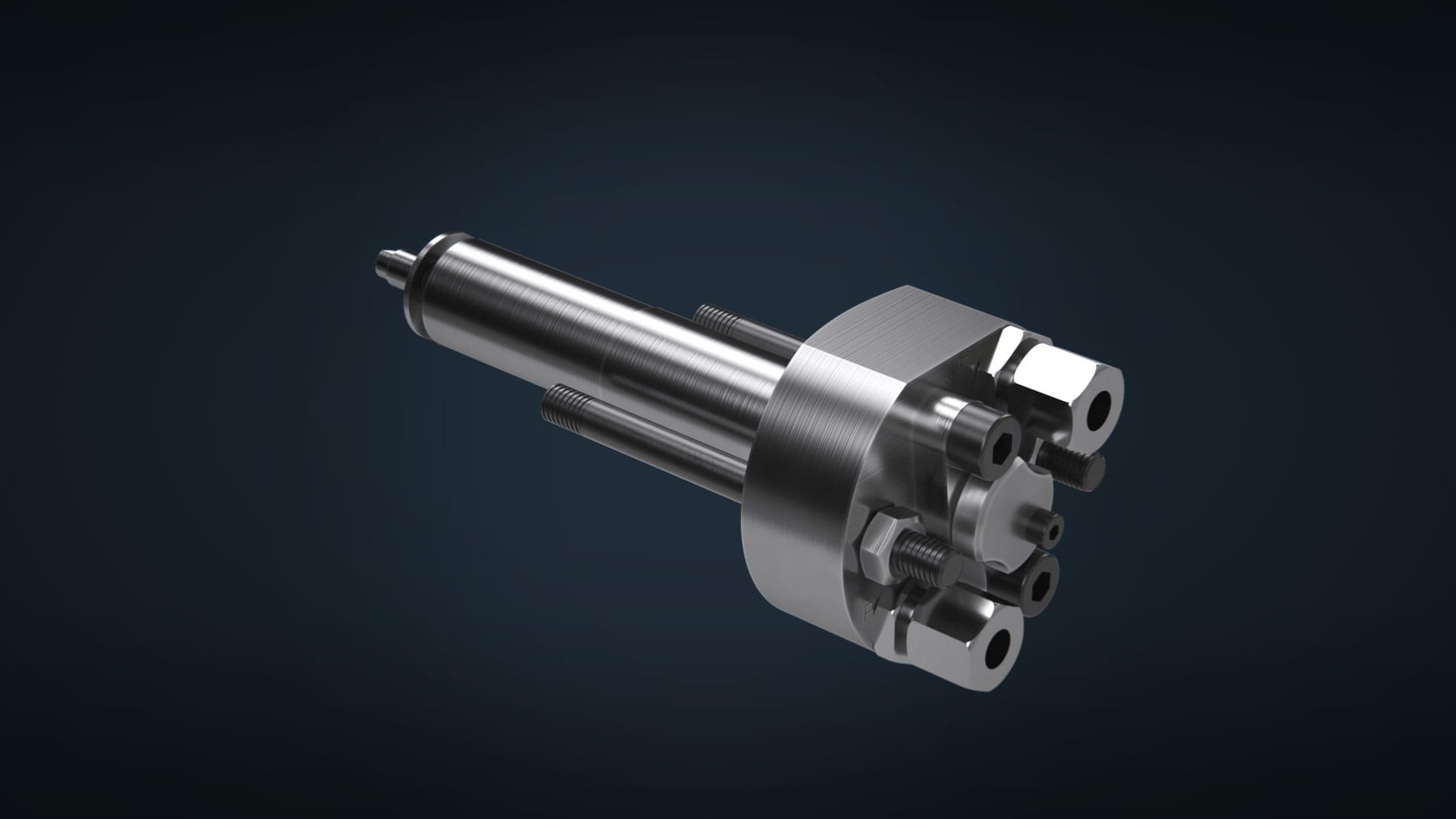

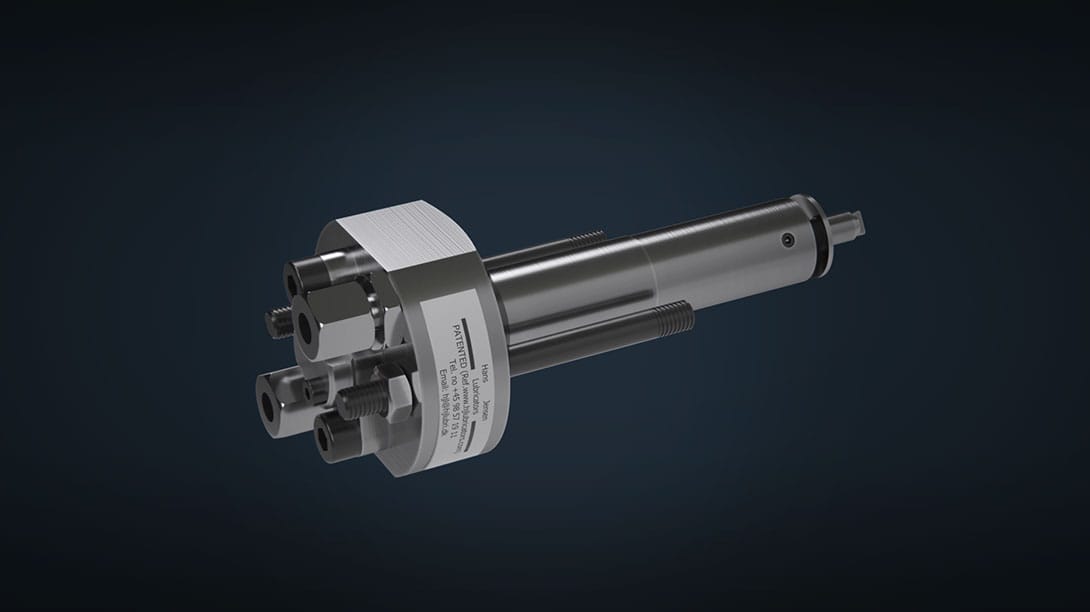

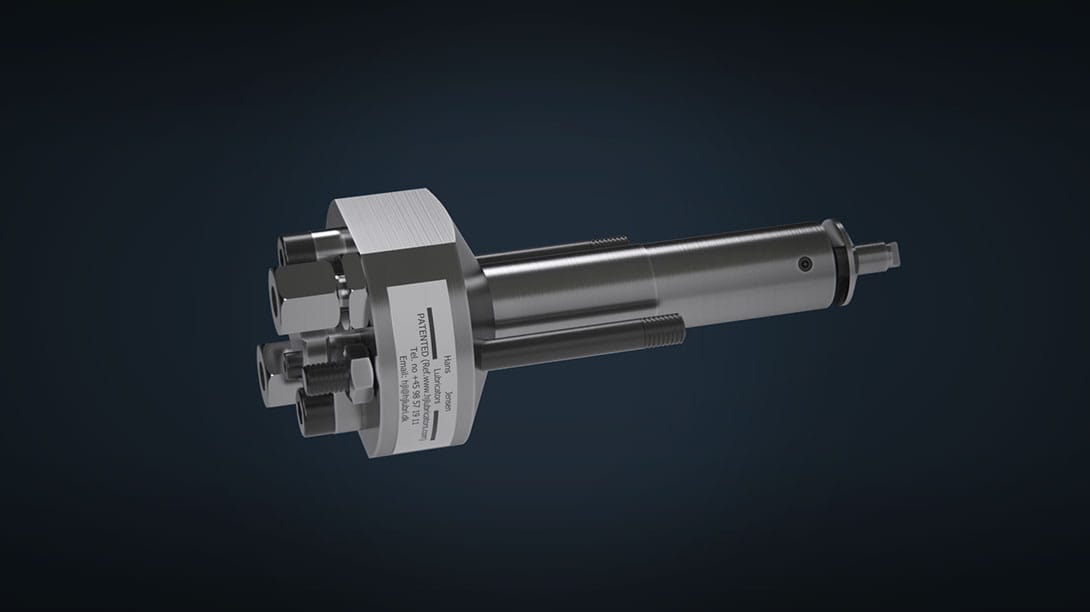

HJ LUBTRONIC 2.0

HJ Lubtronic 2.0 is an electronically controlled cylinder lubricator that adjusts feed rate according to ME load, BN number or sulphur content of the fuel oil. HJ Lubtronic 2.0 works on all engine types and designs.

- Oil injection in every piston stroke

- Atomizing cylinder oil into the combustion chamber

- Automatic load or sulphur dependent feed rate regulation

- Automatic Cleaning Sequence algorithm (patented technology)

- Delta-Timing algorithm ensures lubrication both into the ring pack and liner

- Sulphur-, load- and BN-dependent algorithms

- Possibility for online monitoring and preventive alarms

-

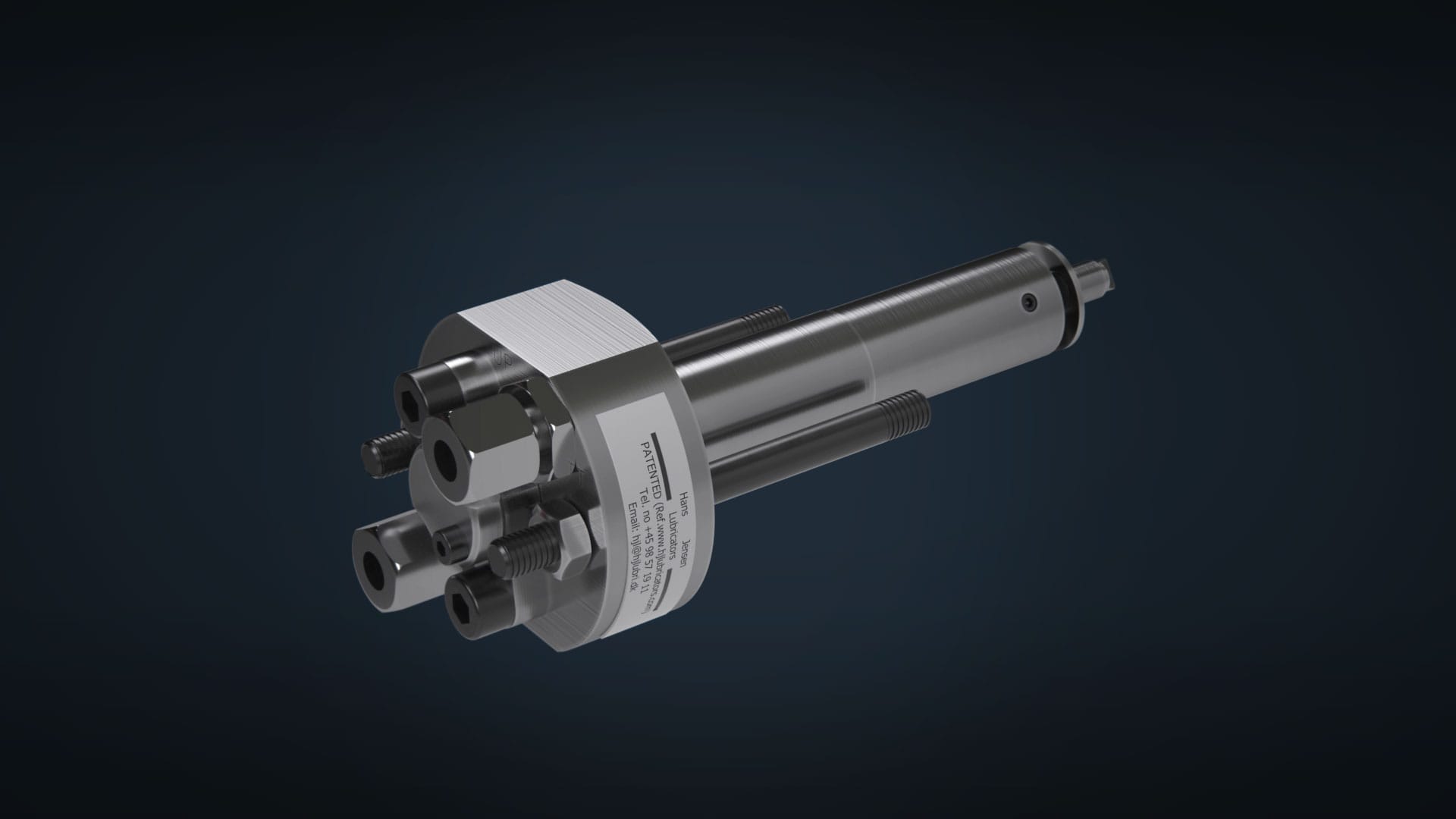

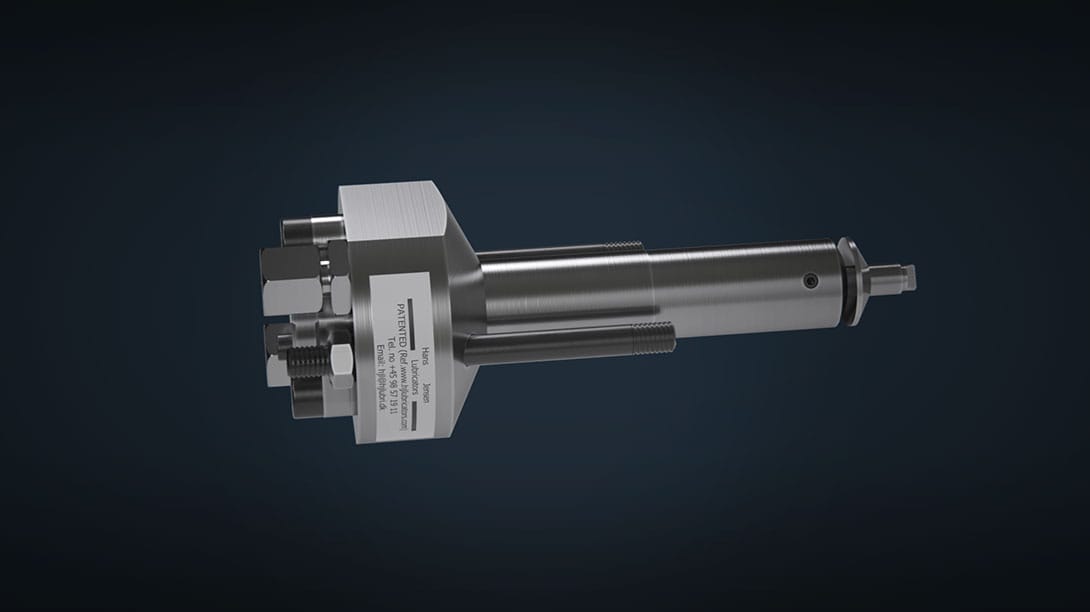

Over pressure sensor

The over pressure sensor is added in order to protect the pressurized parts in the piping system. An alarm is generated if the sensor registers a pressure of 130 bars and above.

If an alarm is activated it means an injection valve is blocked and the system must be checked.

-

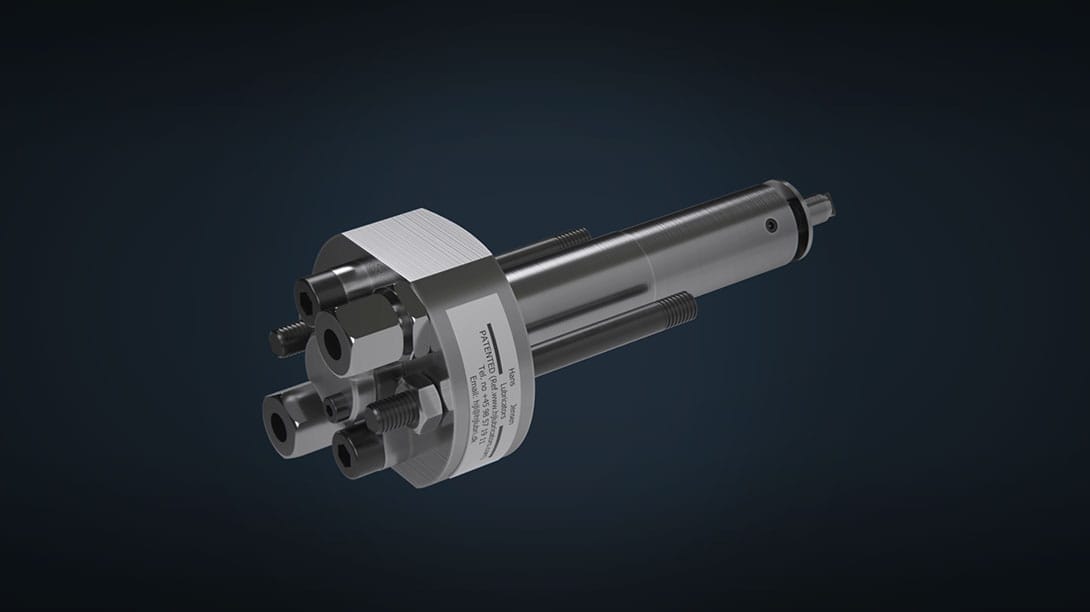

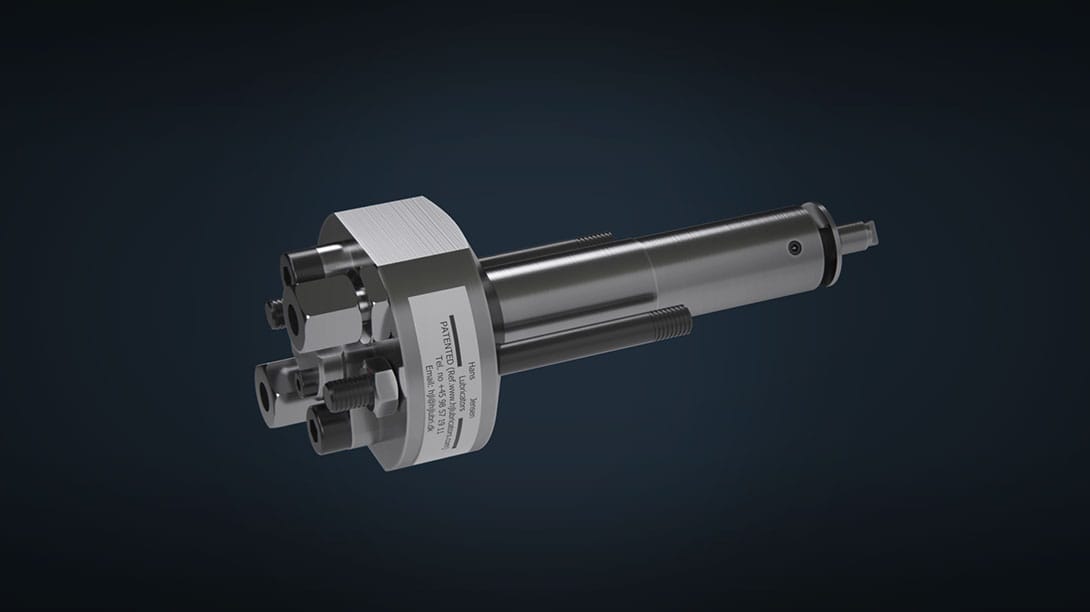

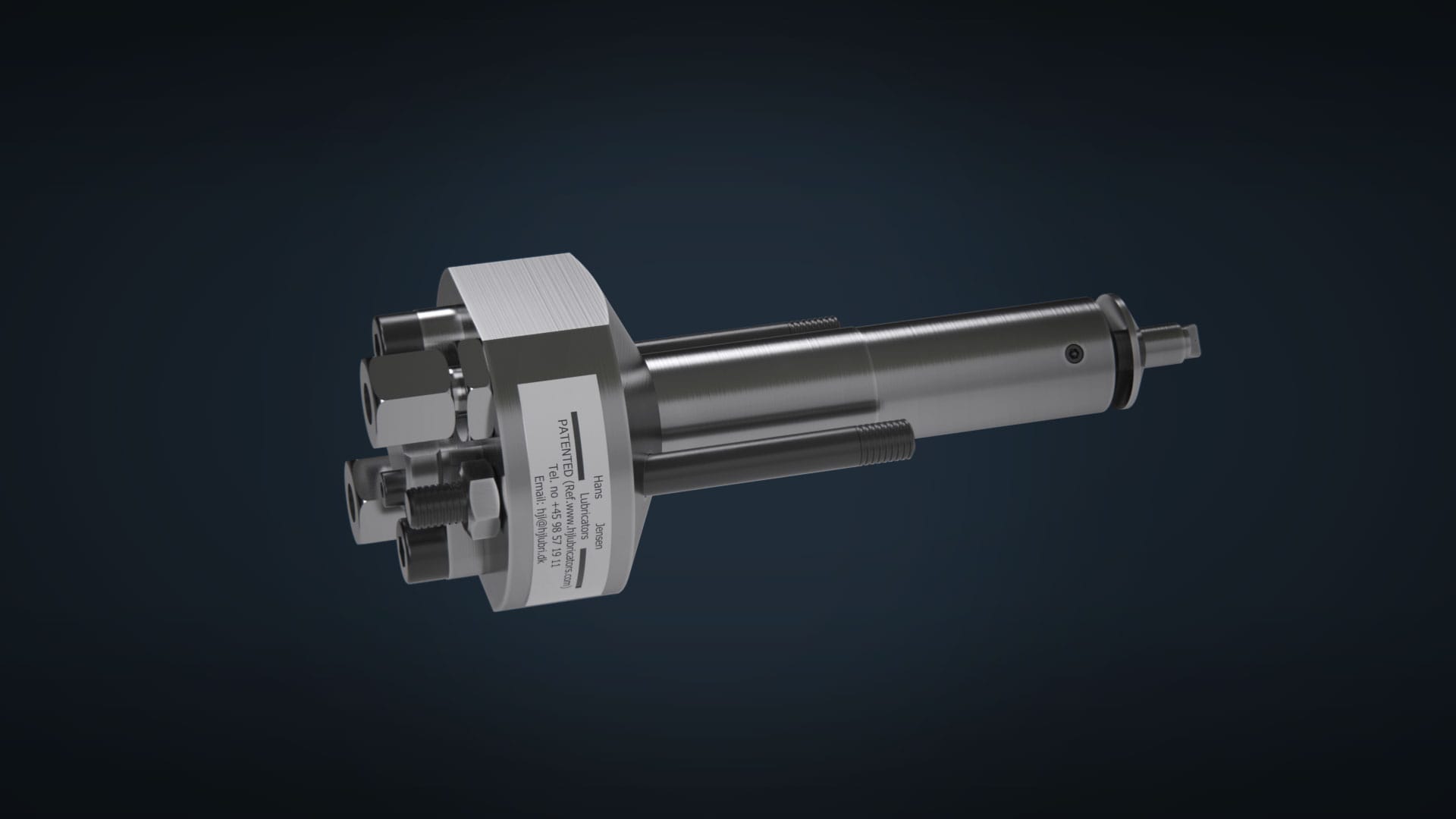

Dual stroke

The HJ Lubtronic 2.0 works on a dual stroke principle, meaning two predefined stroke lengths are set inside the lubricator. The system switches between the two stroke lengths to ensure the correct cylinder oil quantity.

This simplified approach towards regulating the feed rate, means fewer moving parts, while still injecting fresh oil into the cylinder at every piston stroke under normal operating conditions.

-

Flow sensor

The flow sensor is added as another measure of security. The aim of the flow sensor is to detect whether oil flows from the lubricator to the injection valve.

If the sensor does not detect an oil flow an alarm is generated.

-

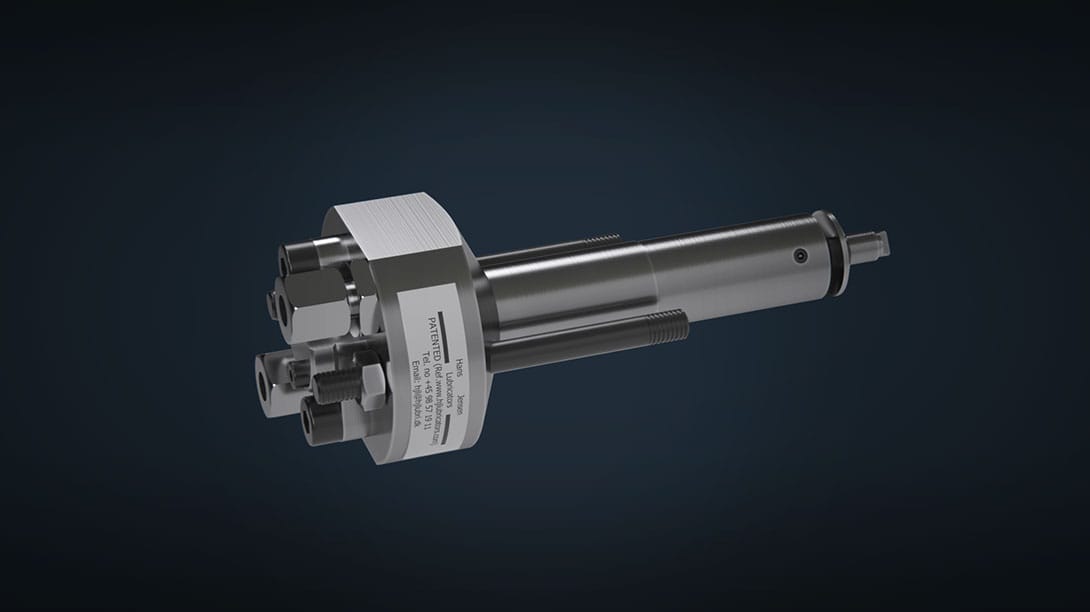

Solenoid valve and lube check sensor

The solenoid valve receives an activation signal. The signal activates a hydraulic valve that opens for the pressure. This moves the pistons up and supplies oil to each lube point.

With the dual stroke technology, the two valves control one stroke length each.

When the pistons move up, there is a check sensor to confirm movement. If the pistons have not moved after 5 strokes the system will automatically use the other valve as backup and an alarm or a warning will be generated.

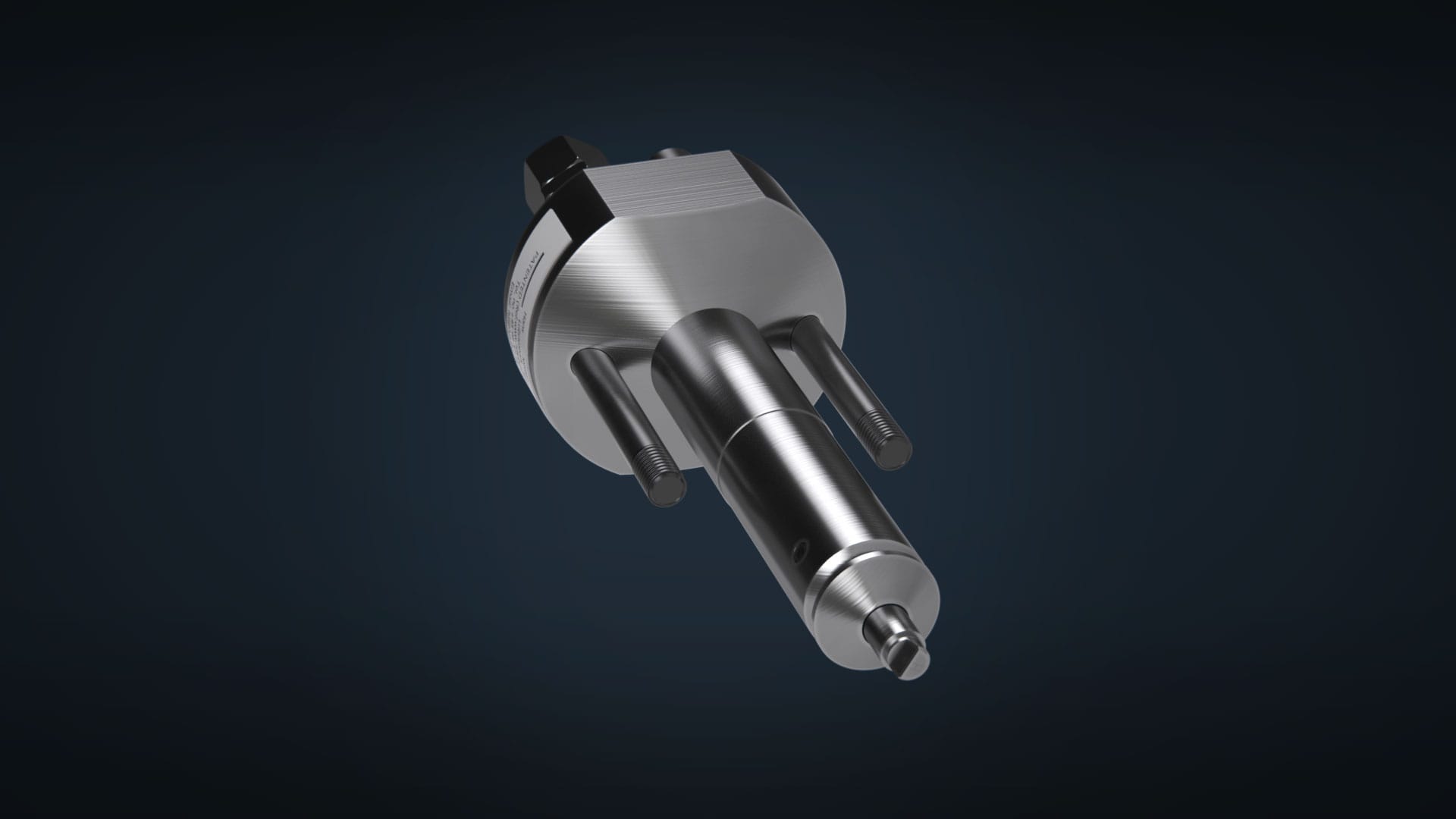

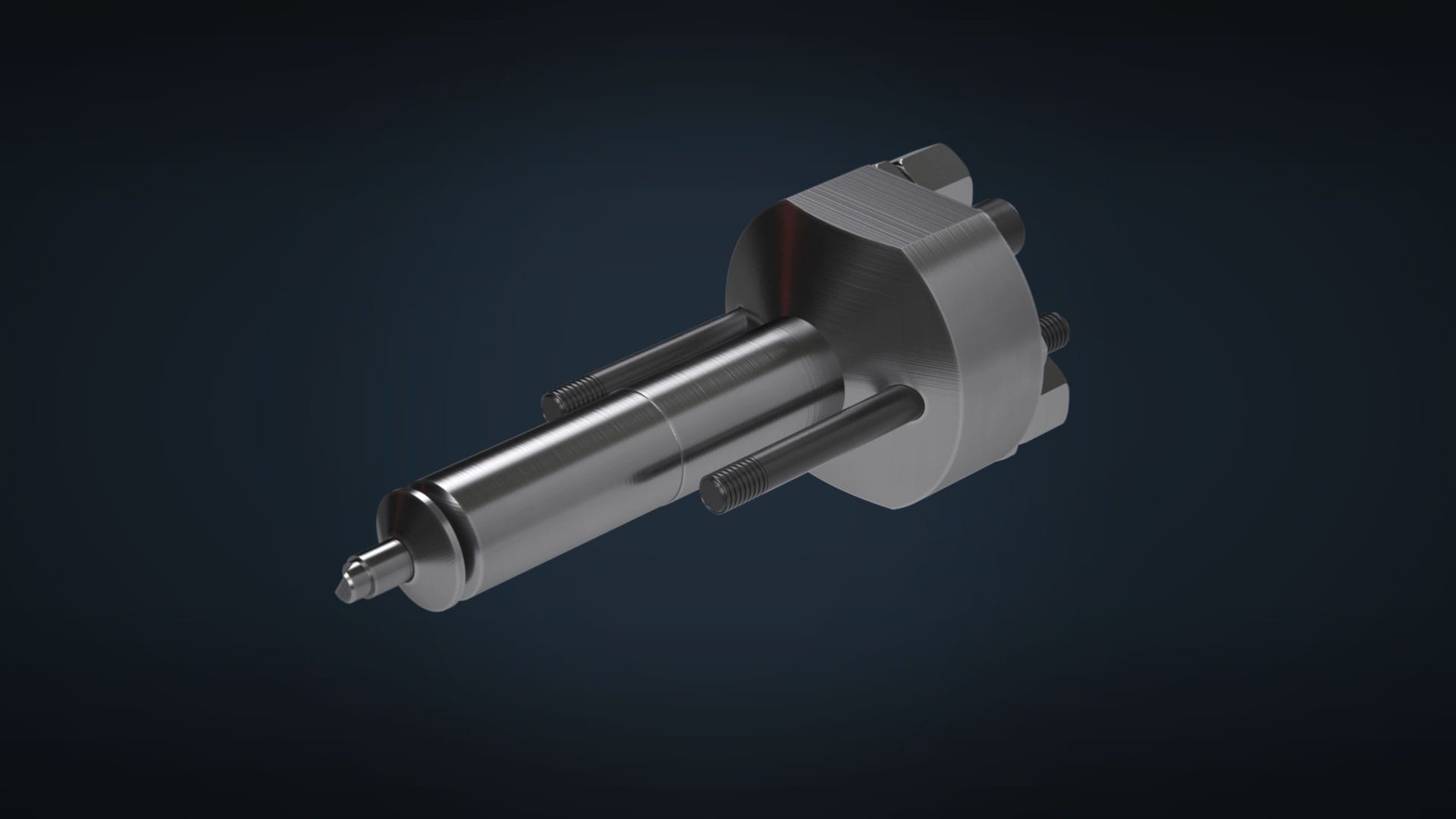

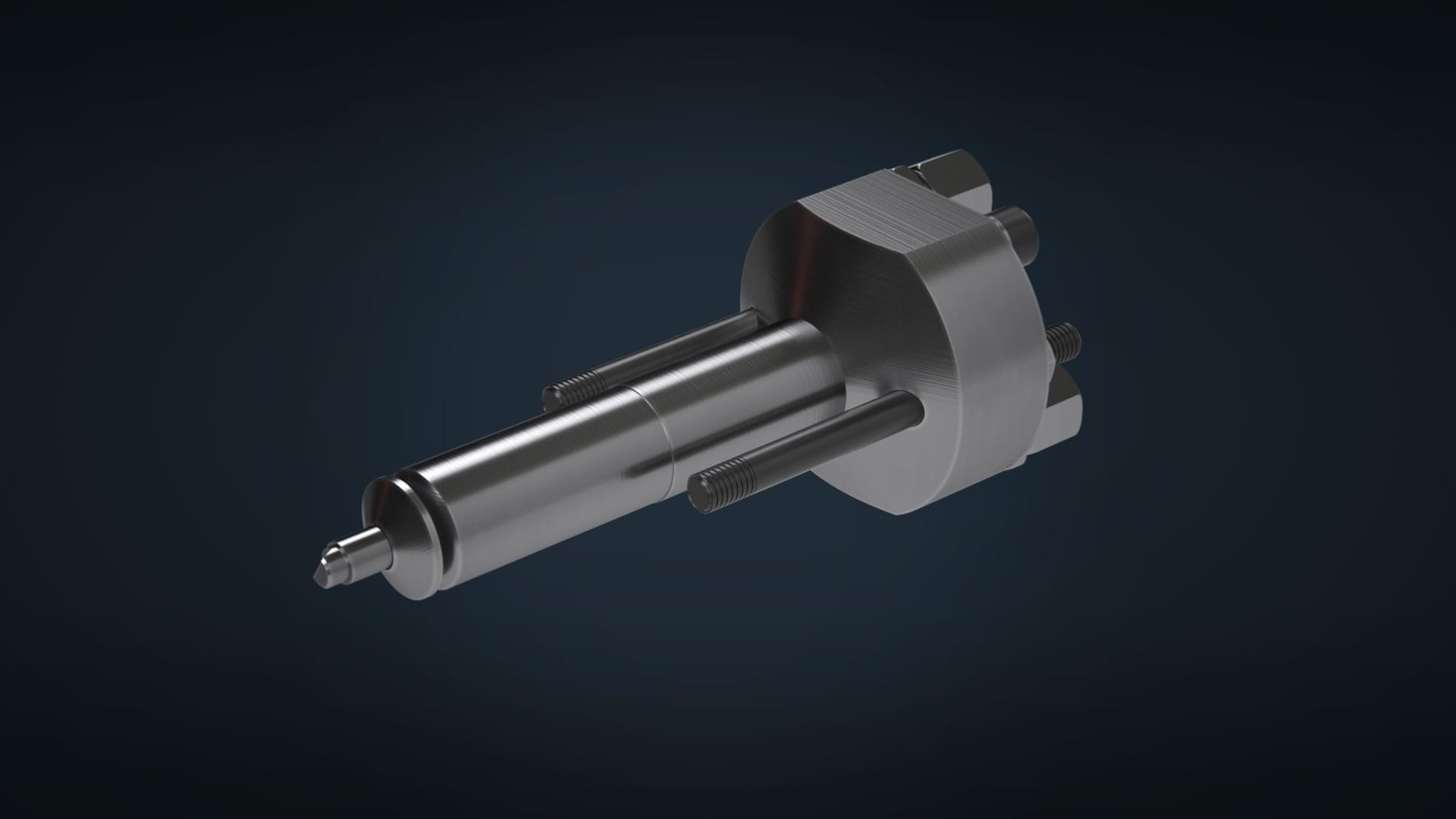

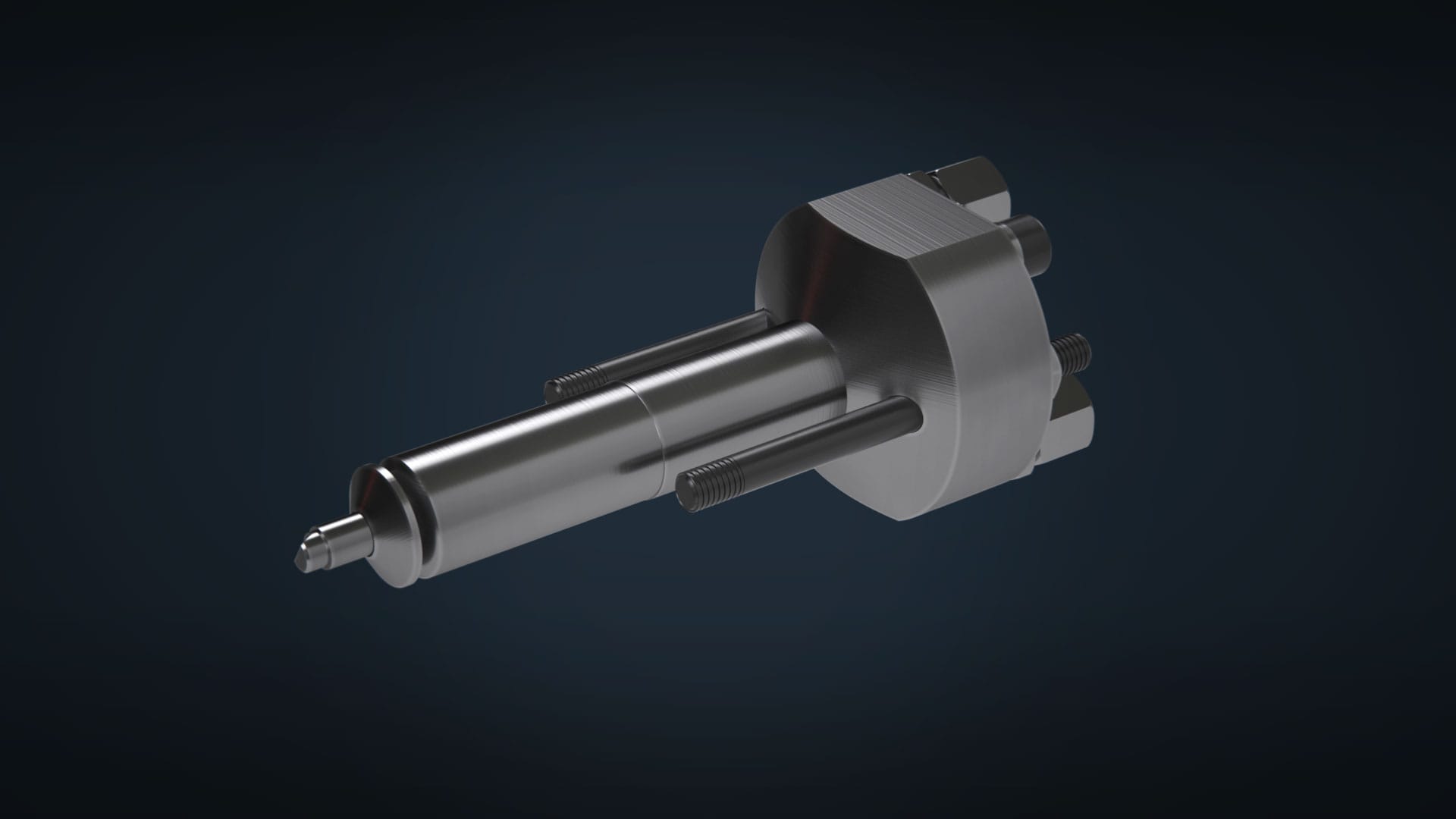

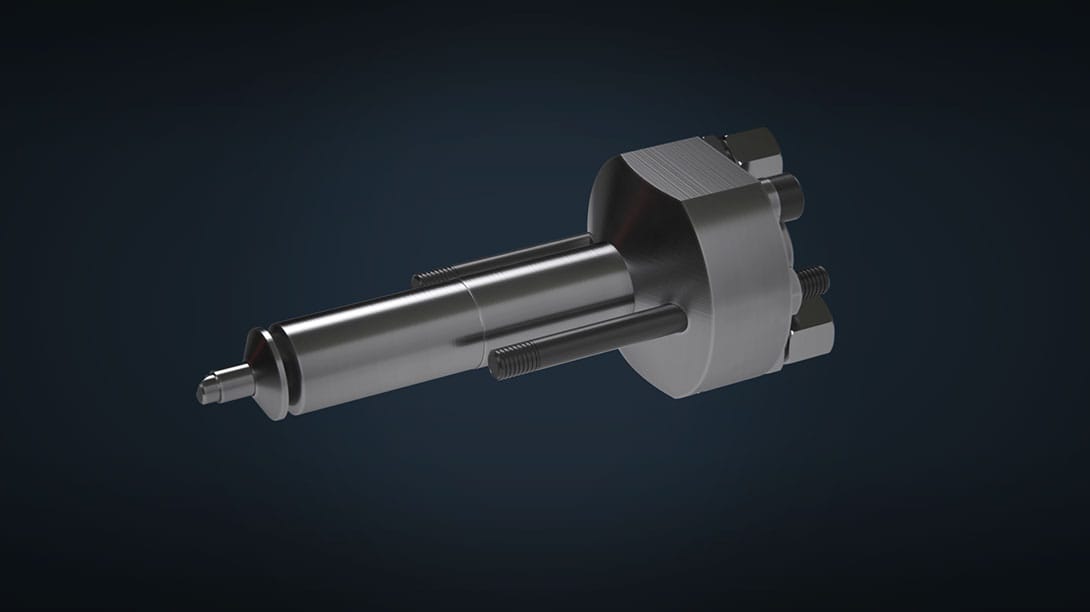

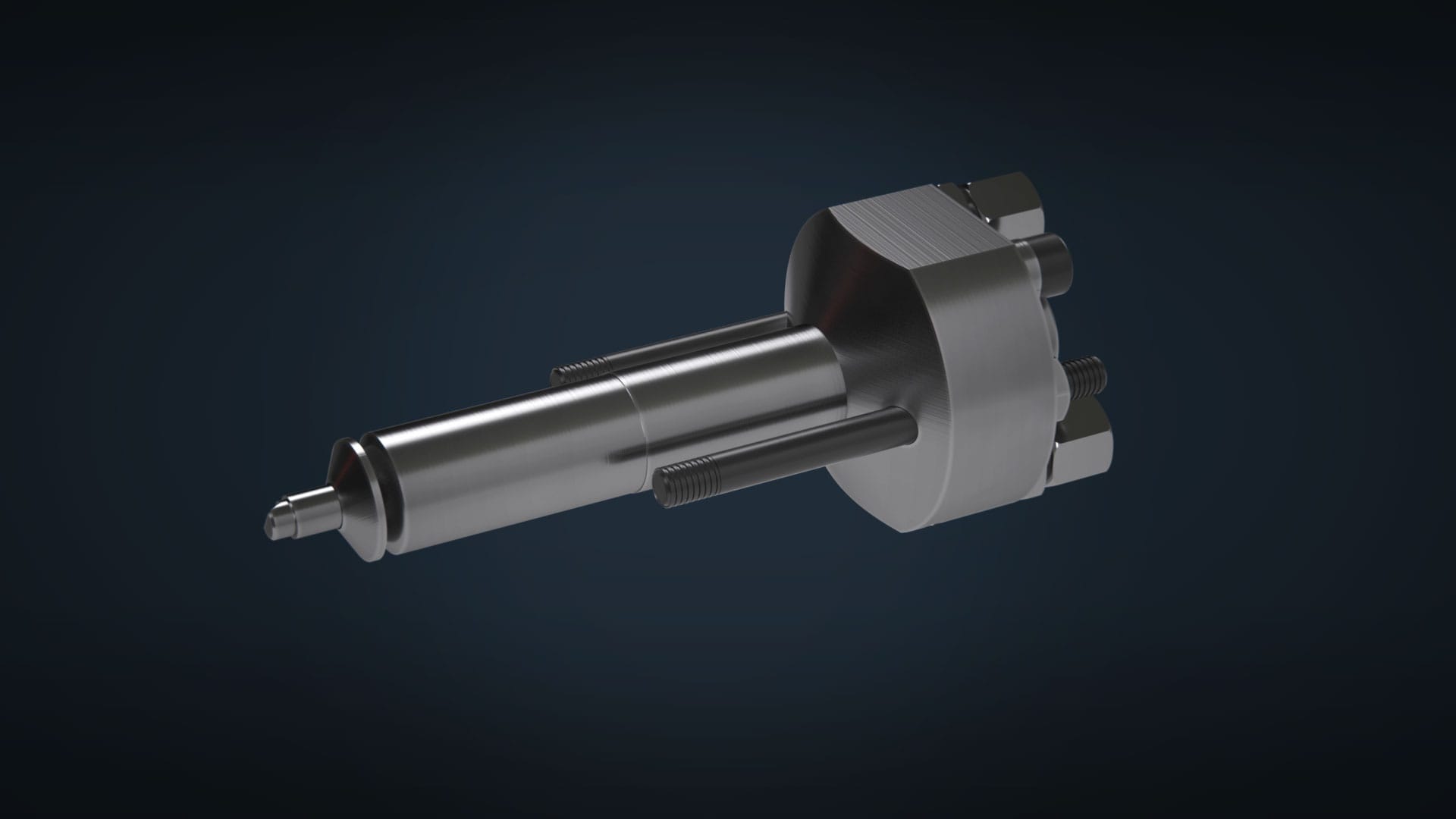

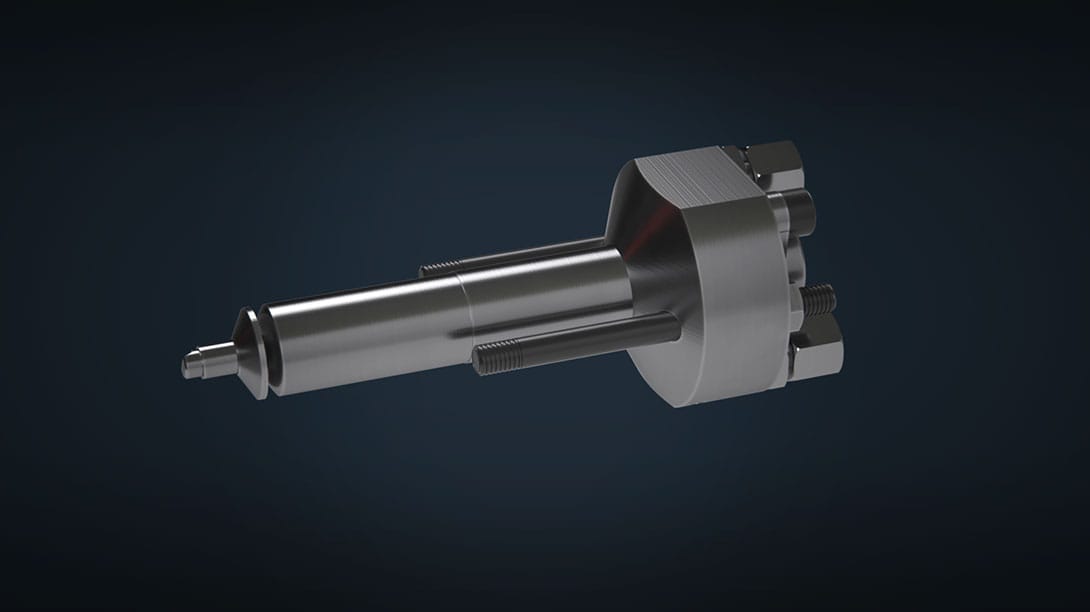

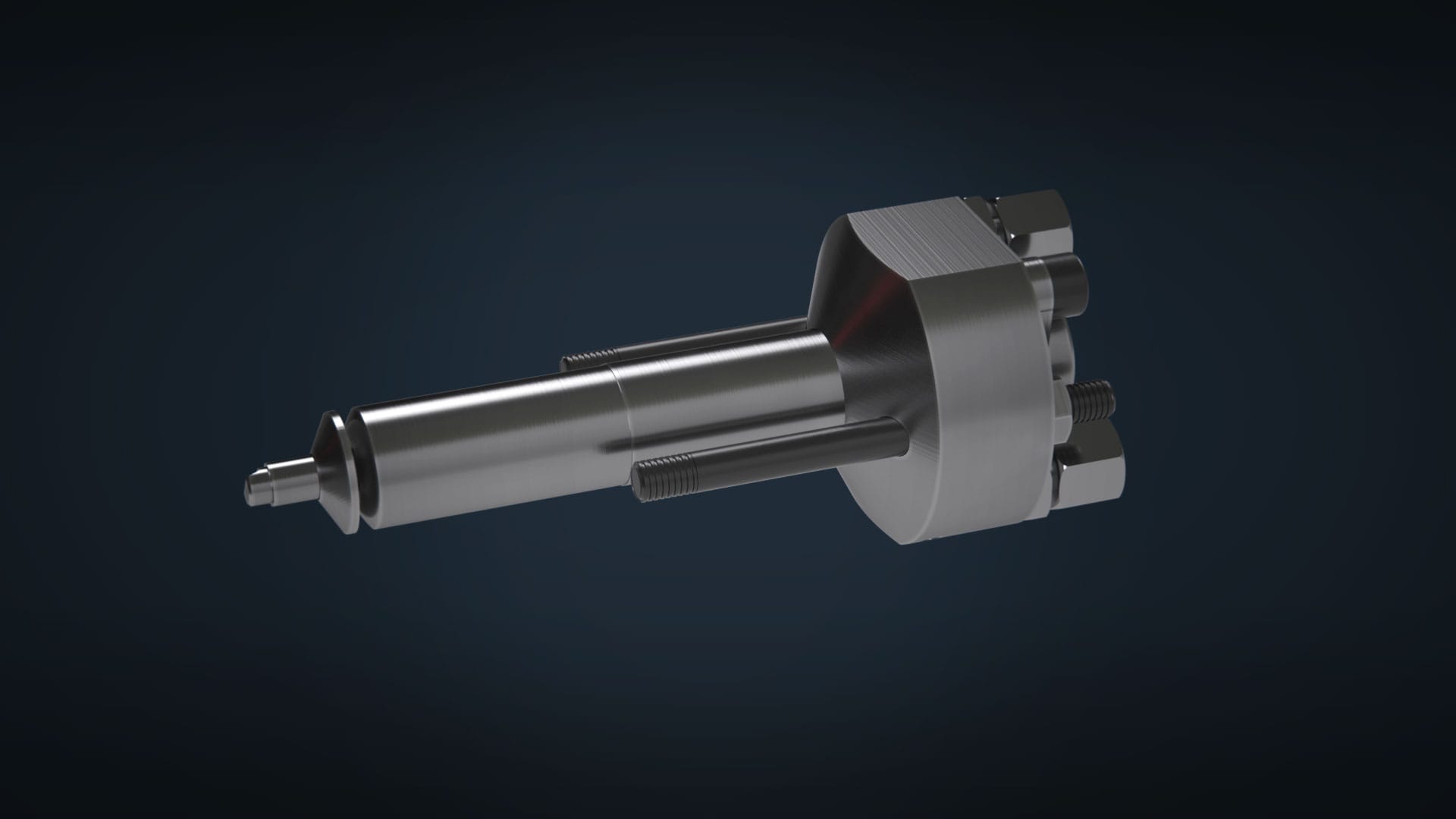

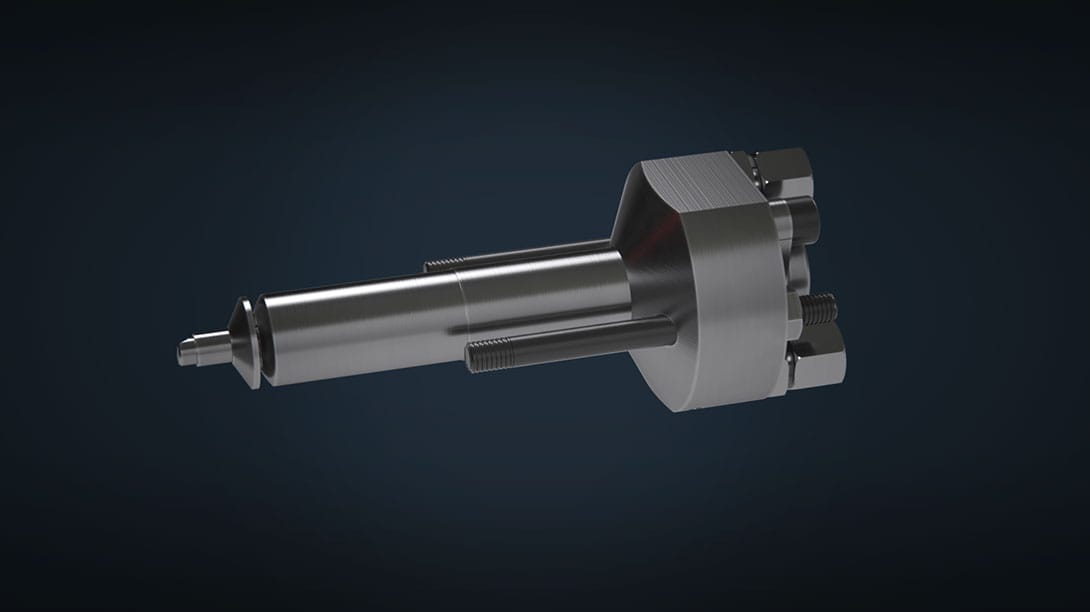

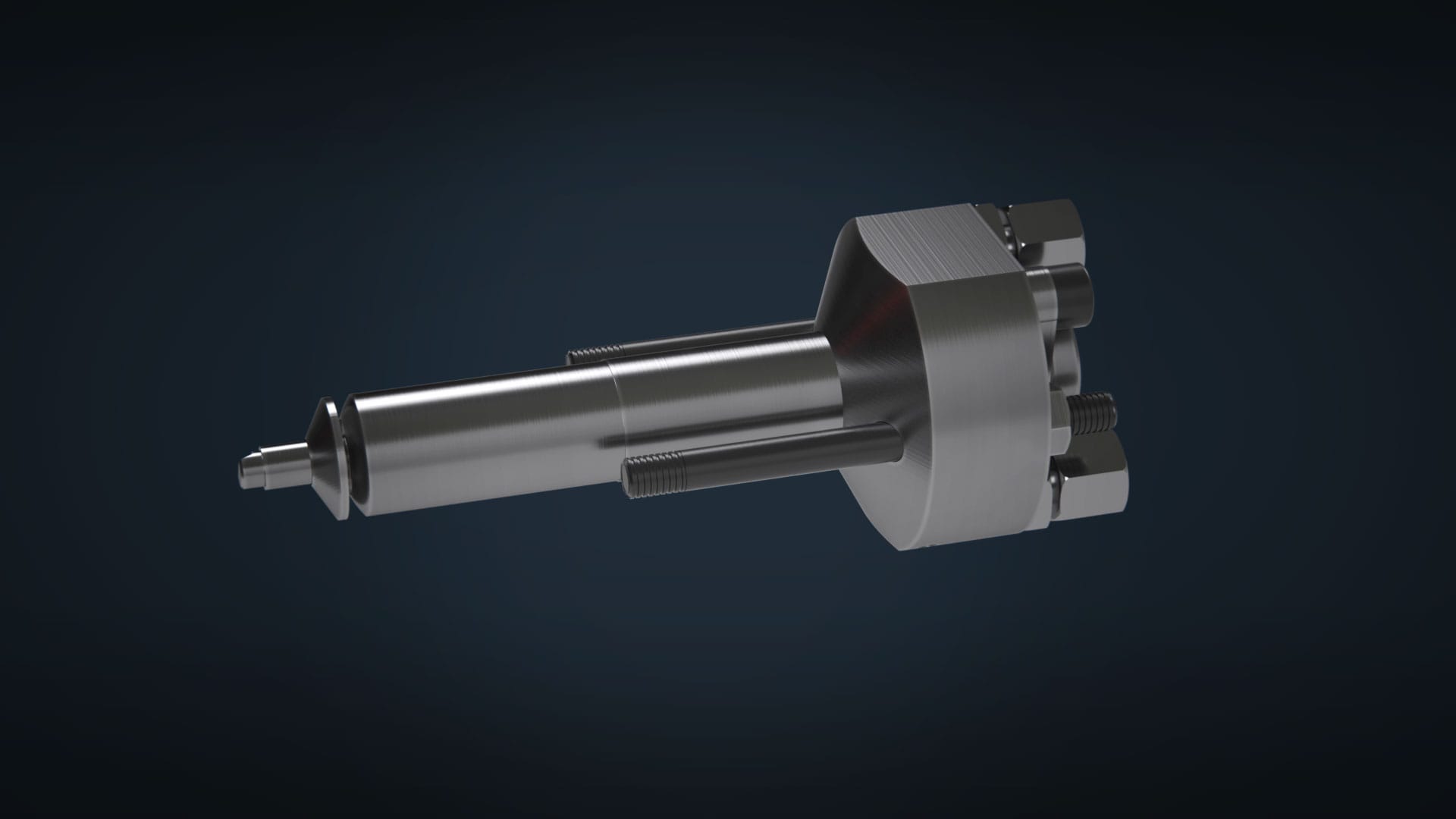

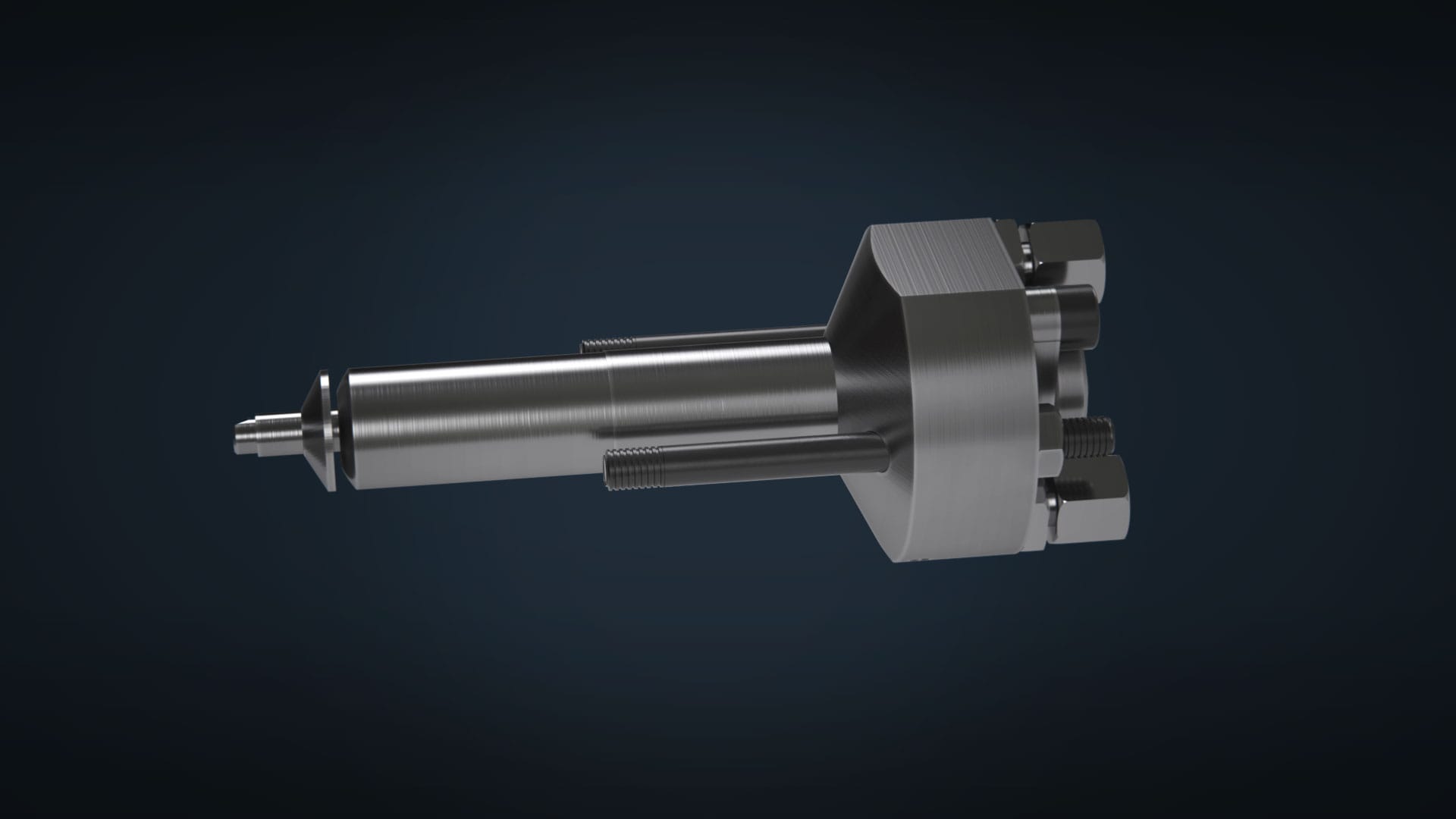

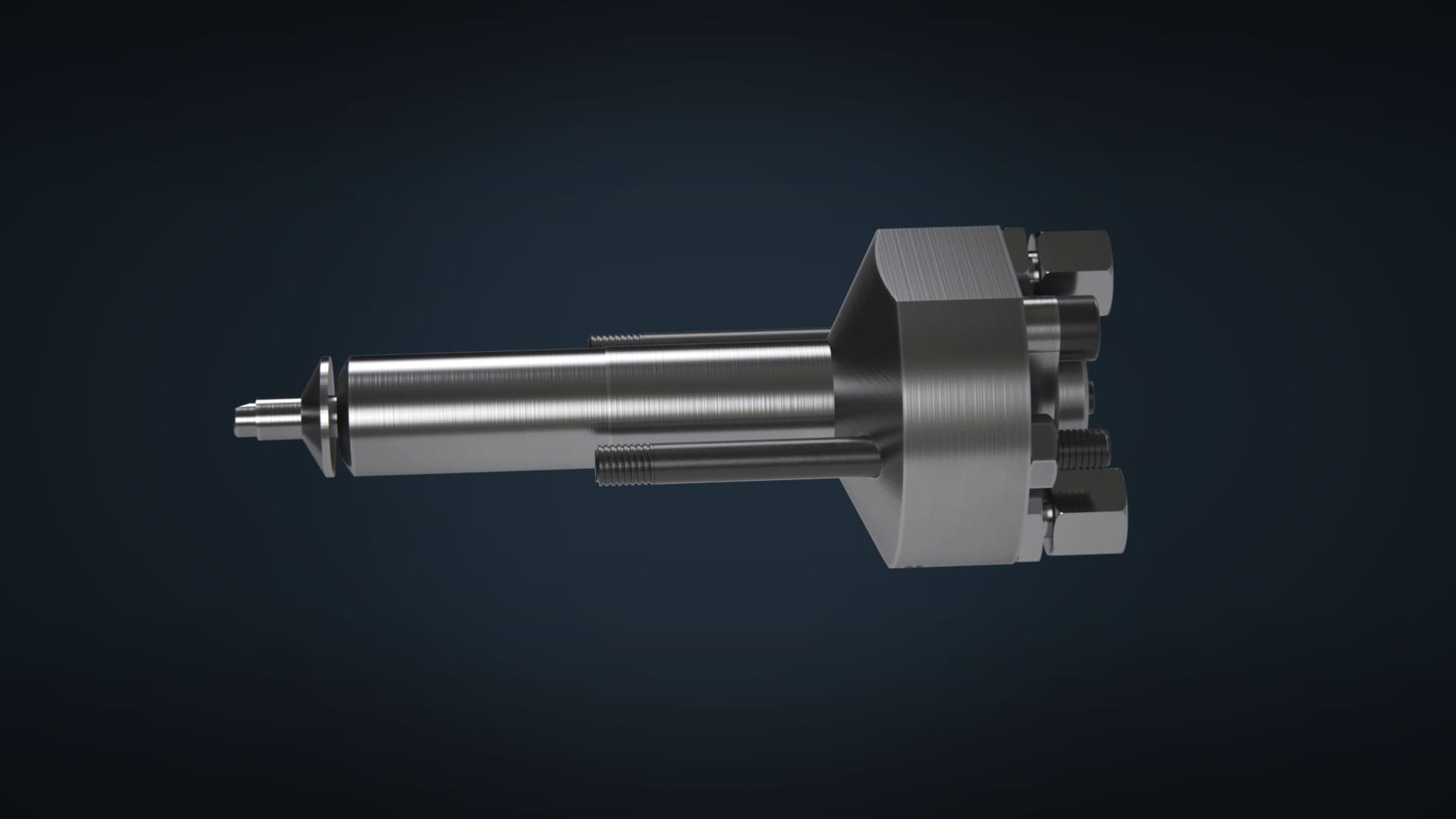

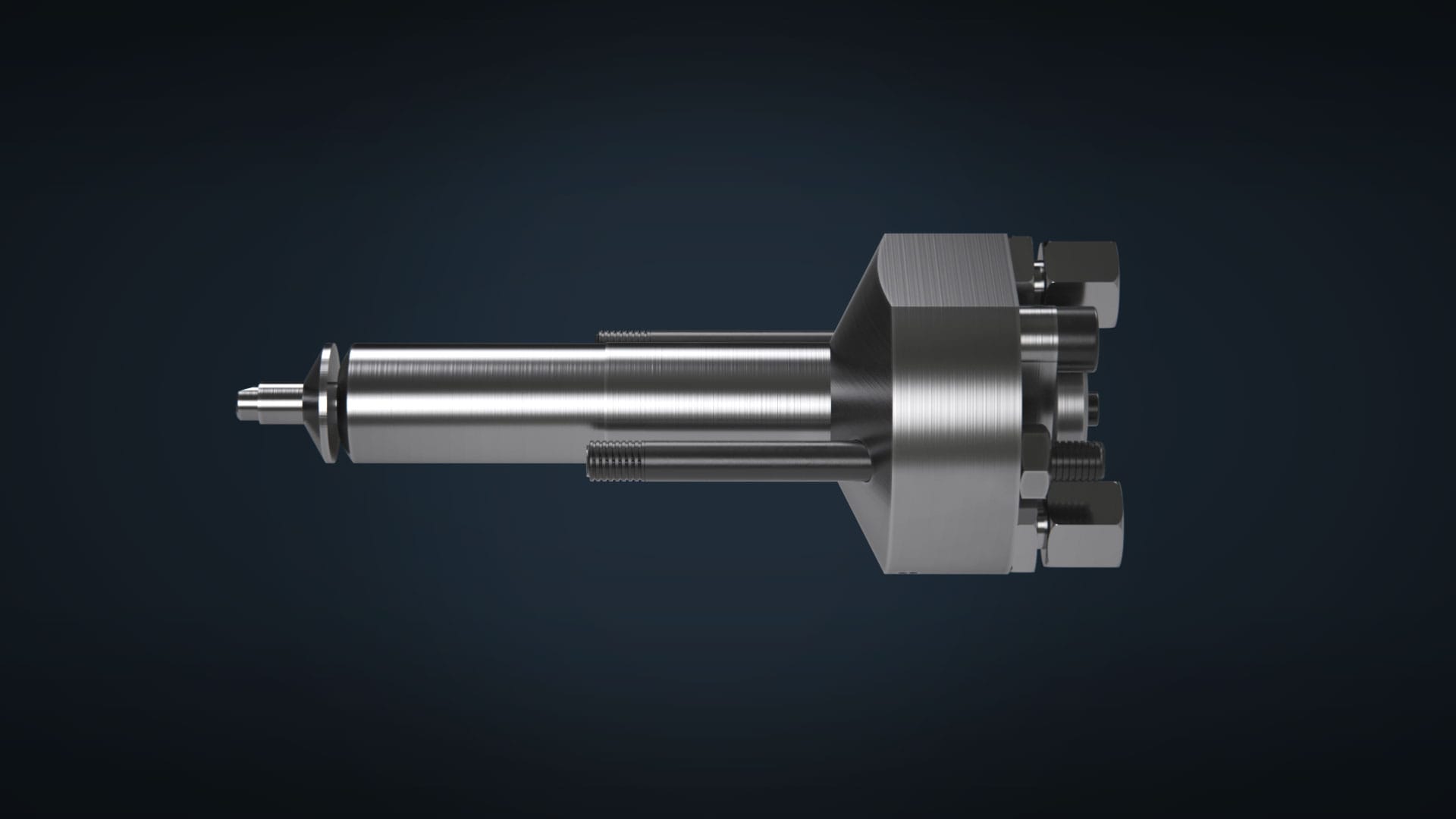

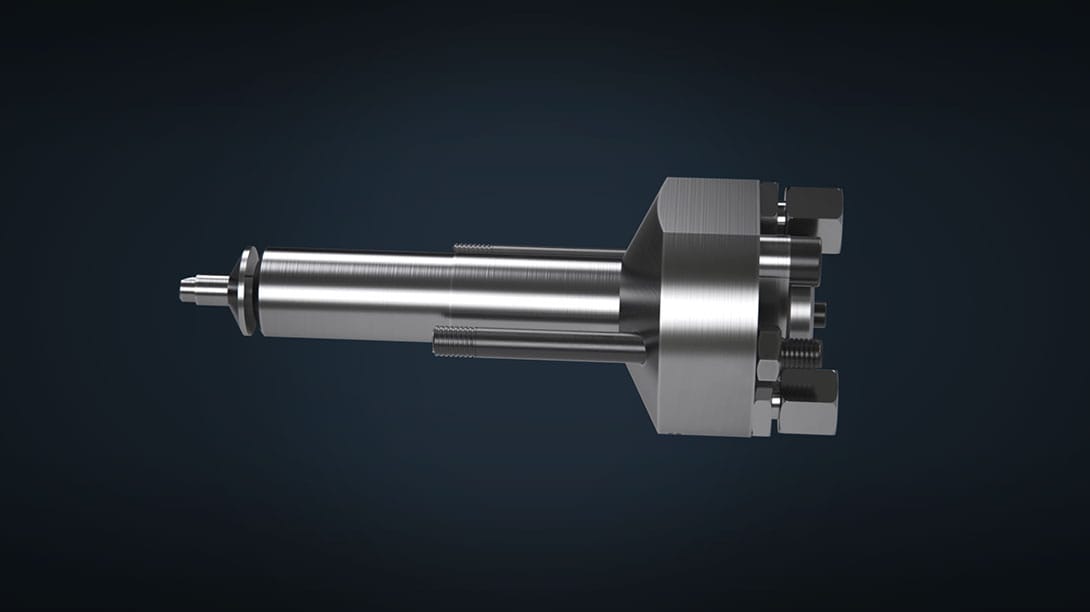

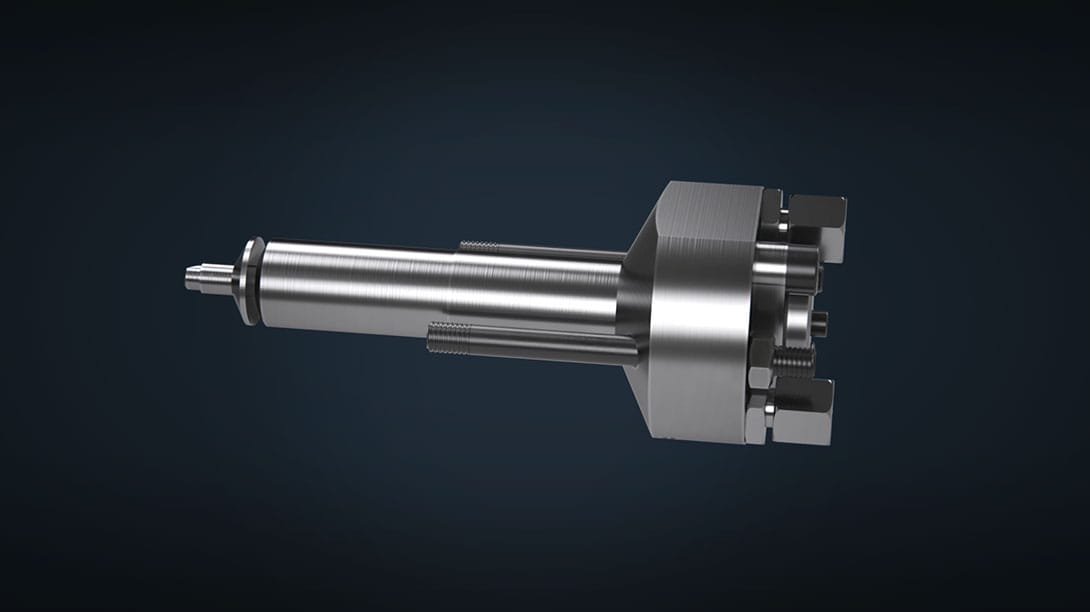

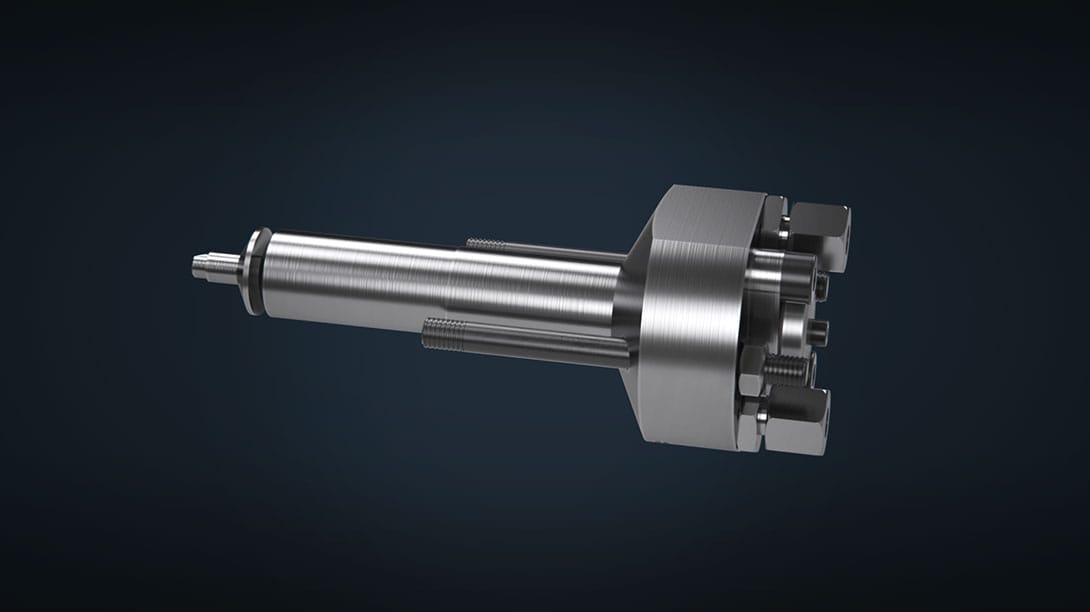

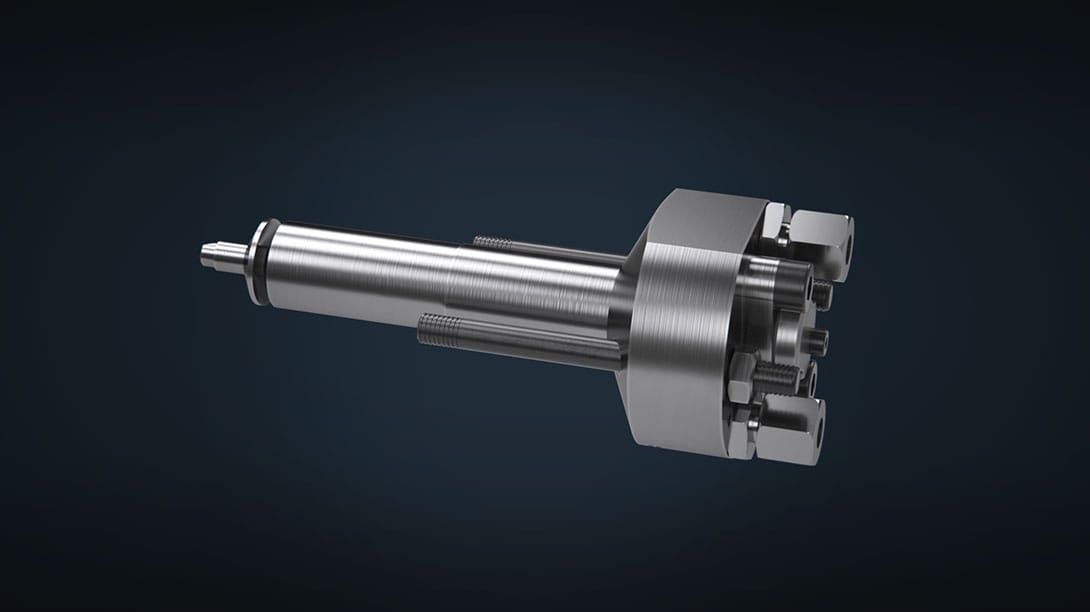

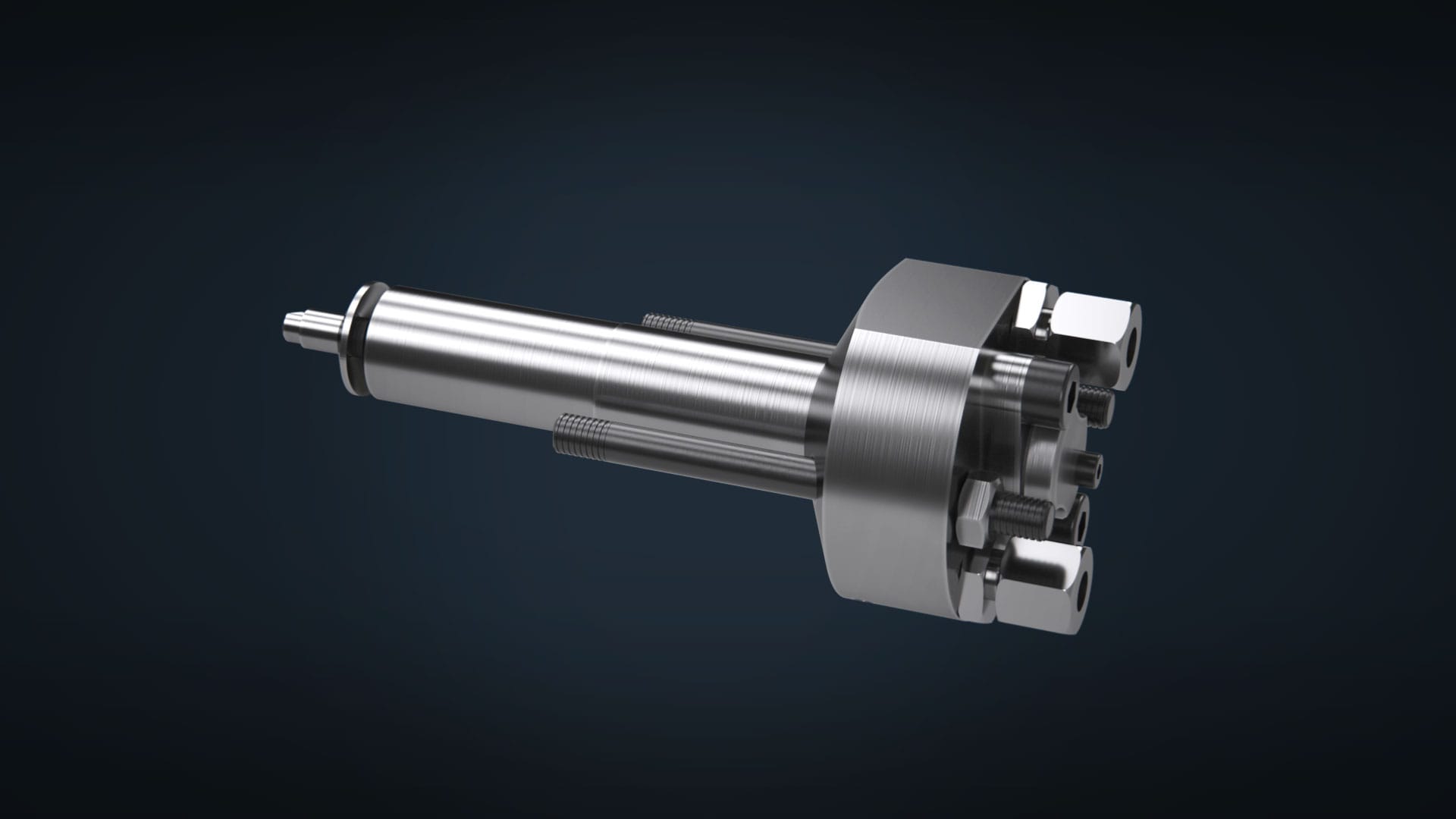

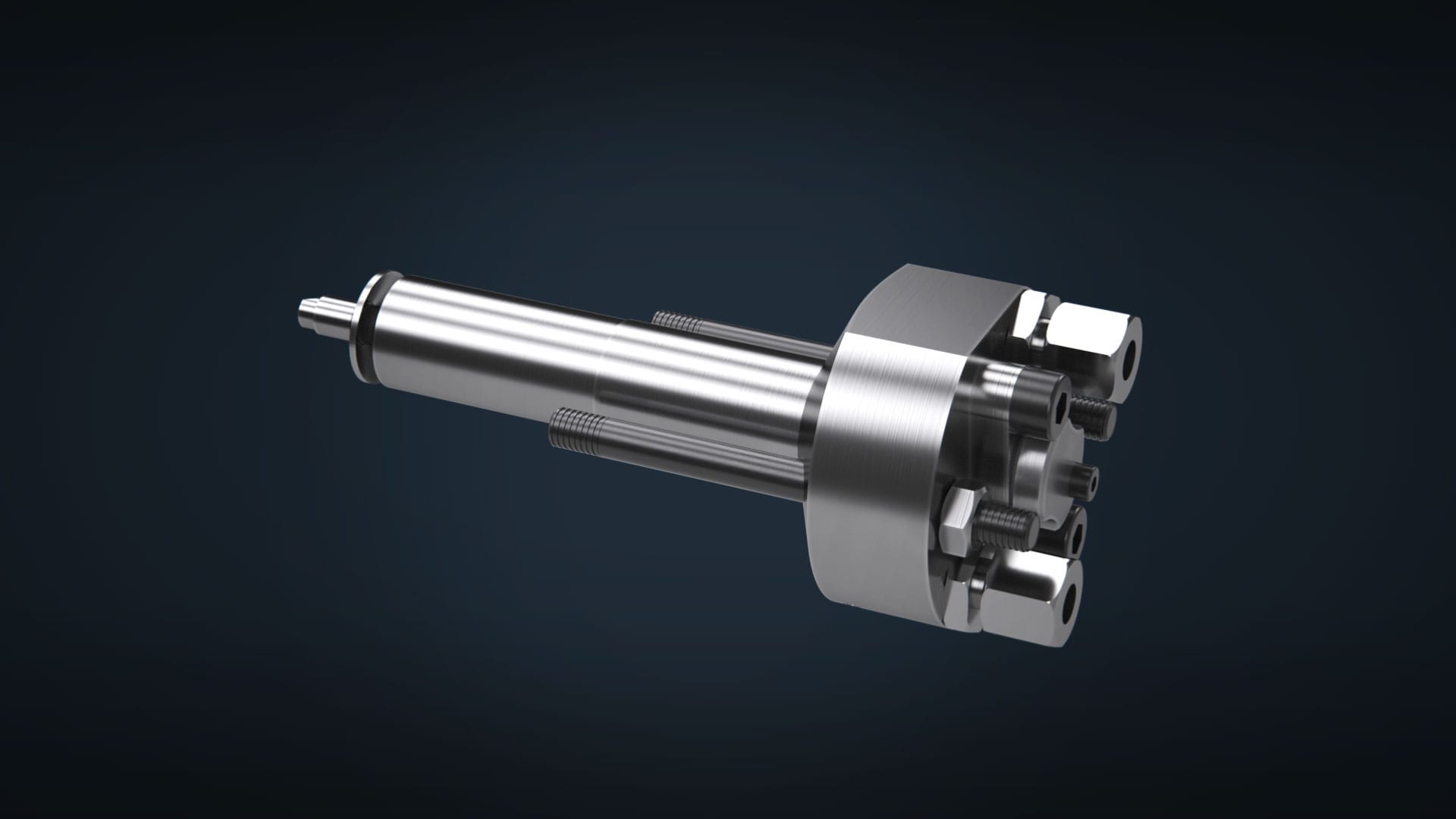

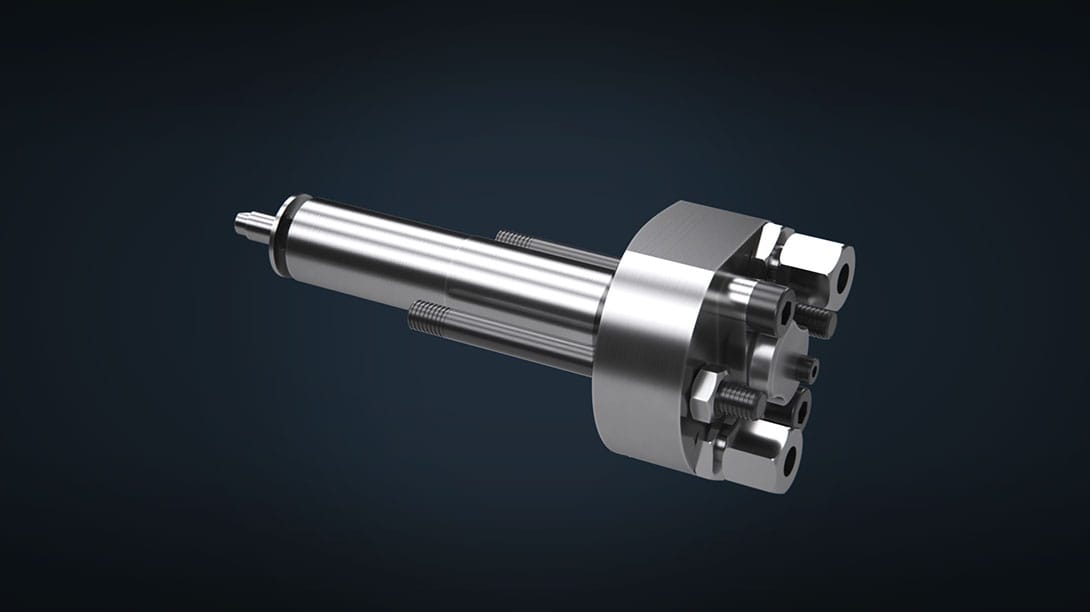

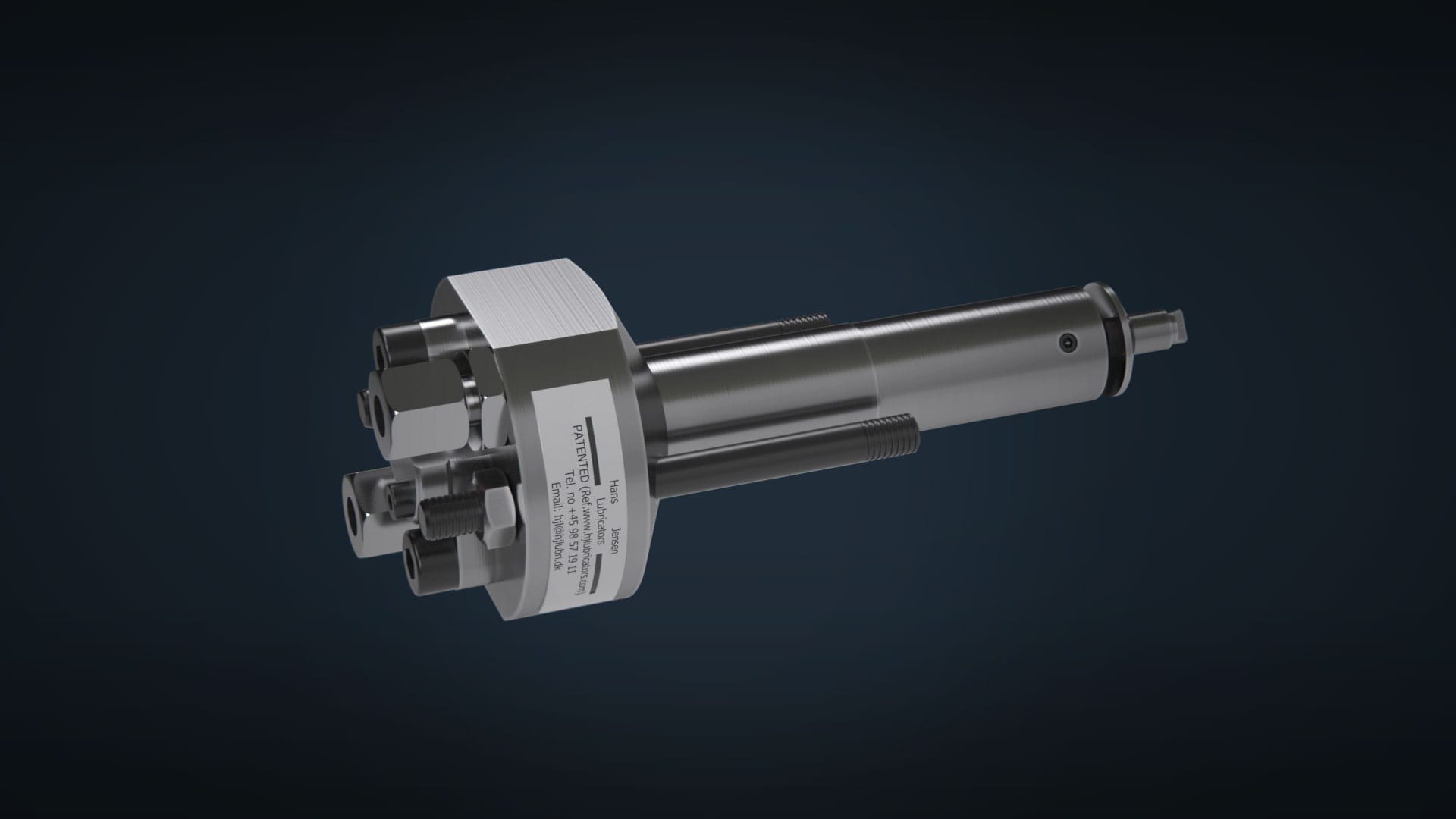

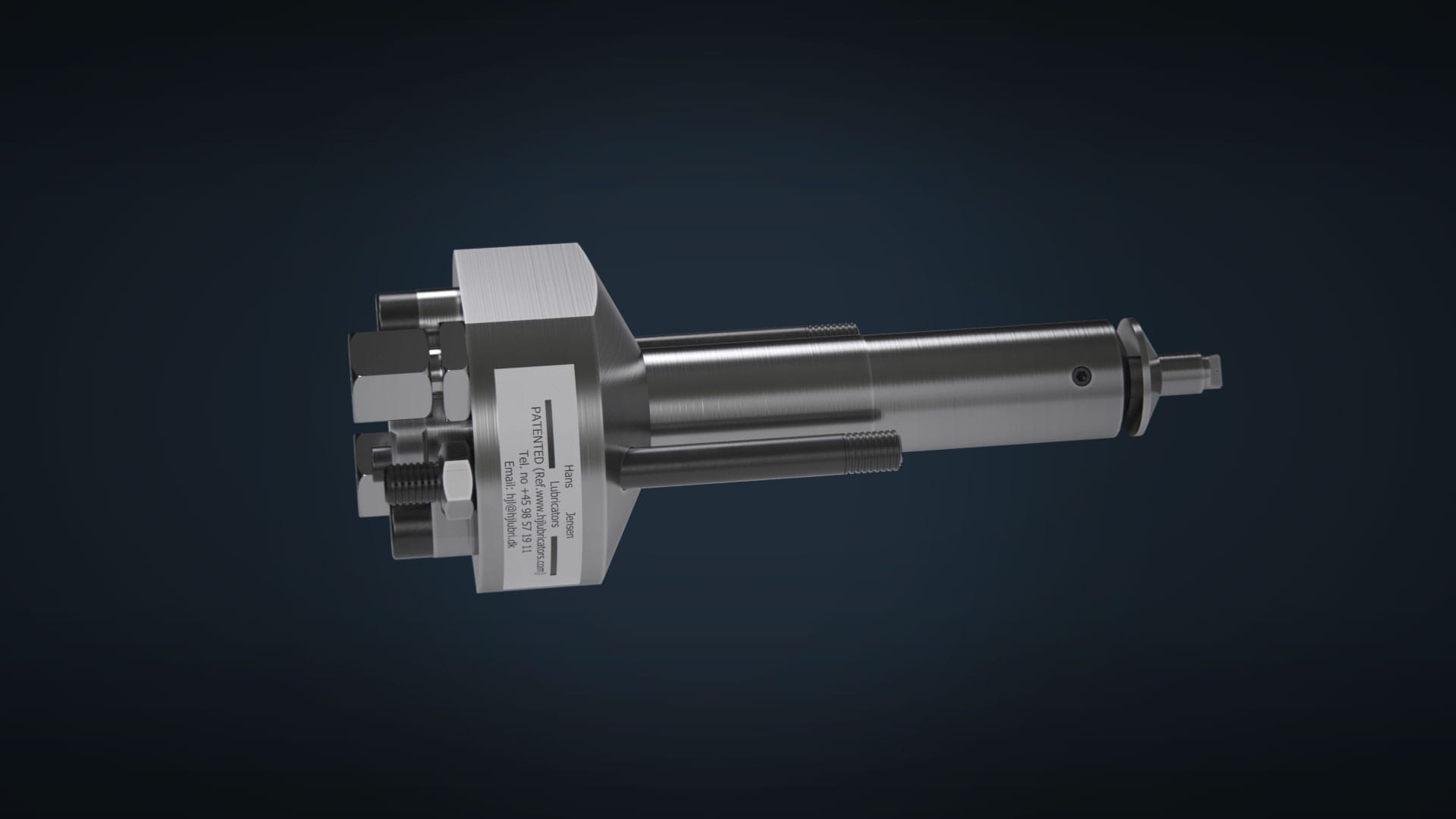

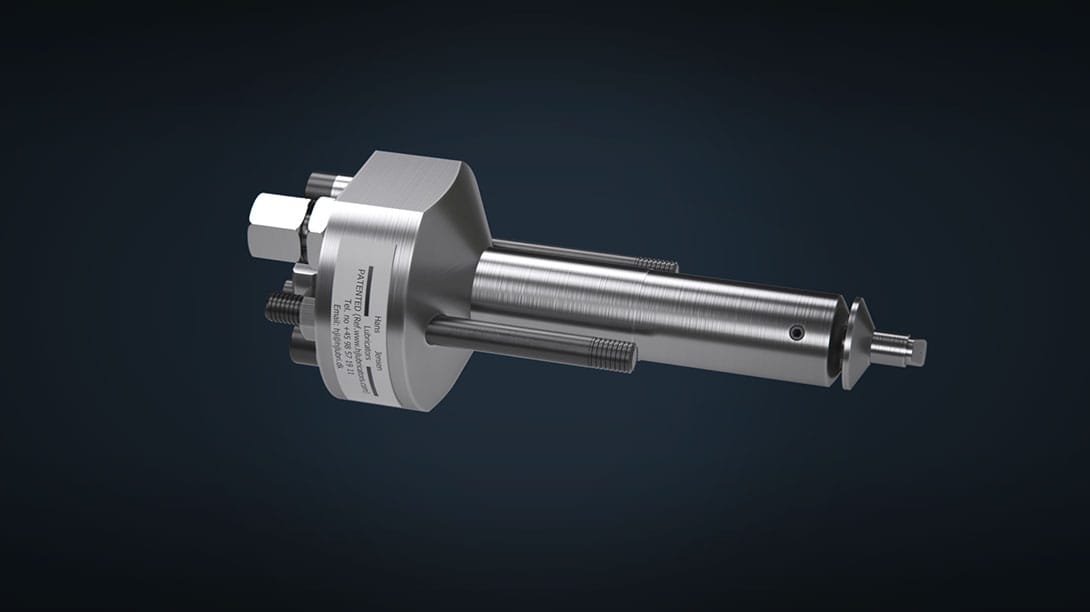

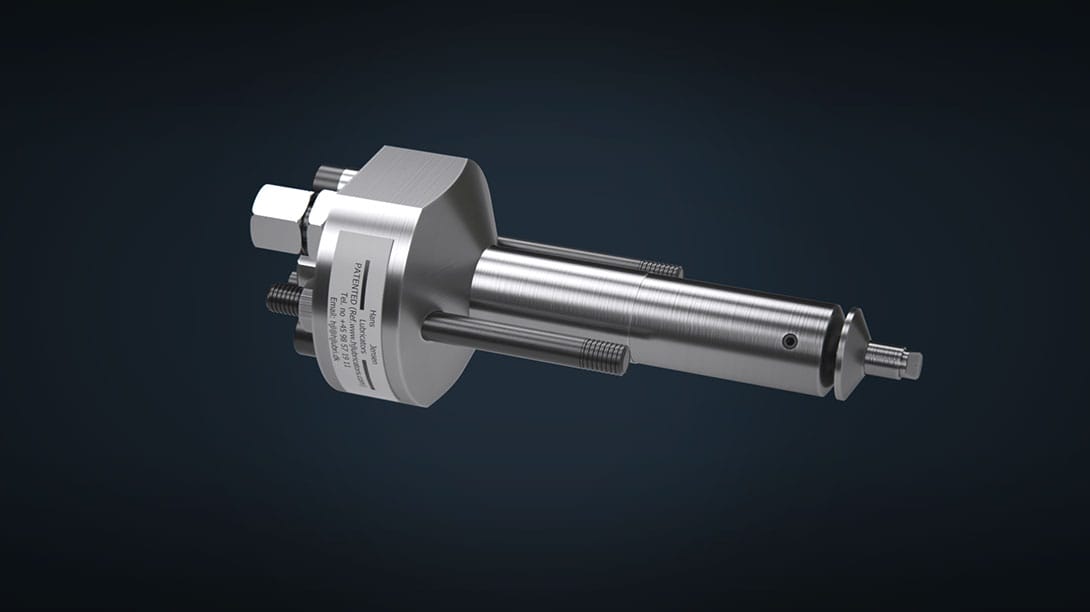

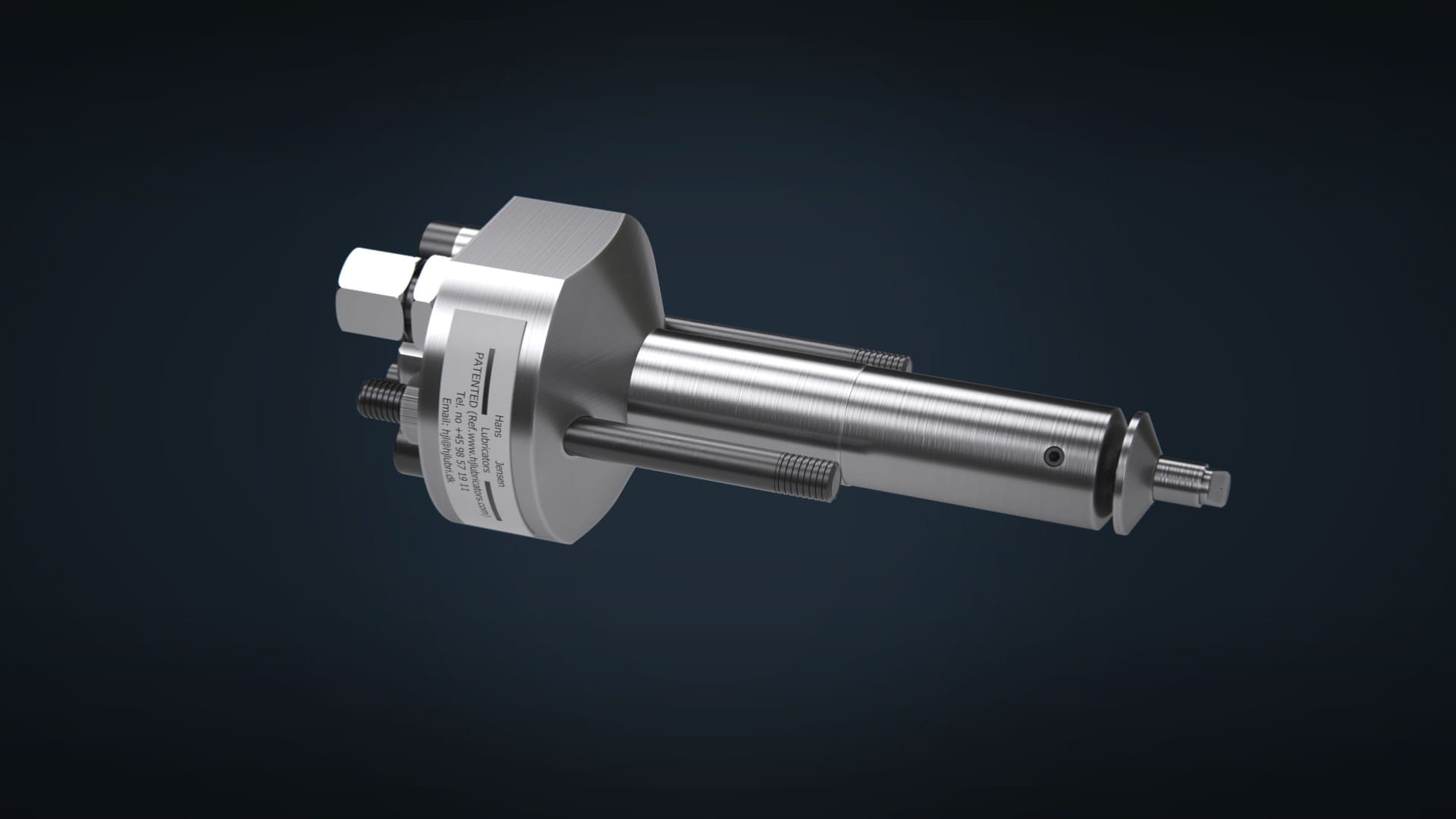

HJ SIP

HJ SIP is a cylinder lube oil injection valve that sprays oil in tiny droplets utilizing the centrifugal power of the scavenging air swirl (”Swirl Injection Principle”), ensuring optimum distribution of injected oil and thus an efficient use of the lube oil. HJ SIP works on all engine types and designs.

Features:

- Fresh oil injection in every piston stroke

- Atomizing cylinder oil into the combustion chamber

- Efficient dispersion on the liner wall and piston rings

- Automatic load or Sulphur dependent feed rate regulation

- Automatic Cleaning Sequence algorithm

- Delta-Timing algorithm ensures lubrication into the ring pack and liner

- Possibility for online monitoring and preventive alarms

-

Nozzle

The cylinder lube oil is sprayed into the cylinder through the nozzle opening. By spraying the lube oil in tiny droplets, into the scavenging air swirl a large surface area of the liner is covered to ensure optimal distribution of the cylinder oil. This in turn, ensures proper utilisation of the oil.

The nozzle opening is turned at an angle and injects the oil upwards onto the upper part of the cylinder liner where it is most needed, overlapping the next HJ SIP injection point.

-

Pressure plug

Adjustment of closing pressure (35-60 bar) of the HJ SIP valve is done by an adjustable screw on top of the pressure plug. The adjustable screw is kept in place by a lock cover and a screw.

-

Drain pipe

The drain pipe (T) is for the leak oil internally in the HJ SIP valve and is connected to the return pipe where the oil will be recirculated into the system.

-

Pressure pipe

The Pressure Pipe (P), is the oil inlet side of the HJ SIP valve.

The pressurized oil is pumped from the lubricator.

A strainer is mounted in the inlet of the HJ SIP valve at delivery. This must be removed after 500 running hours.